Medium & Large Hydraulic Press and Progressive Stamping Solutions | Maw Hung

Maw Hung Industrial specializes in medium & large hydraulic press and progressive stamping, offering metal forming, tooling design, automated production, and high-quality solutions for automotive, machinery, and hardware industries.

Table of Contents

1.Technical Advantages of Medium & Large Hydraulic Press Production

2.Progressive Die Stamping Design and Process

3.Industries Served & Product Examples

4.Quality Control and Production Efficiency

5.Customized Solutions & Technical Support

6.How to Choose the Right Metal Stamping Process for Your Project

7.FAQ

8.Contact Maw Hung Email: mawhung7612296@gmail.com

1. Technical Advantages of Medium & Large Hydraulic Press Production

(1) High Tonnage Hydraulic Press Applications

Maw Hung is equipped with 200 to 800-ton hydraulic presses, capable of forming thick plates and high-strength metal materials, suitable for automotive structural components, machinery parts, and hardware housings.

(2) Stability and Precision in Metal Forming

Low-speed, high-pressure hydraulic forming ensures smooth surfaces and precise dimensions, achieving consistent, high-quality output.

(3) Automated Feeding & Production Efficiency

Integration with robotic arms and automated feeding systems supports unmanned continuous production, reducing labor cost and increasing yield.

(4) Customer Achievements

a. Automotive bumper reinforcements

|

|

b. Front grilles for vehicles

|

c. Seat components and assemblies

|

|

|

|

d. Various automotive parts

|

|

|

|

2. Progressive Die Stamping Design and Process

(1) Optimized Die Structure Design

Die stations are engineered based on part geometry and tolerance requirements, ensuring precision, durability, and long tool life.

(2) Die Maintenance and Longevity

High-hardness steels with surface treatment improve wear resistance and maintain stable performance for high-volume production.

(3) Quick Die Change & Automation

Quick-change platforms and sensor integration reduce downtime and increase equipment utilization.

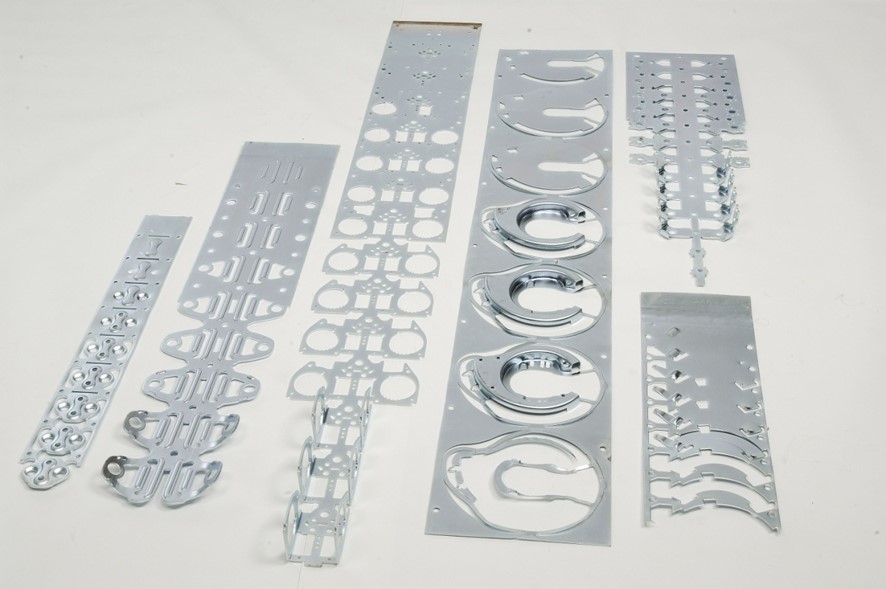

a. Progressive Die Strip

|

3. Industries Served & Product Examples

(1) Automotive and Motorcycle Components

Body structures, chassis parts, engine brackets, and other high-strength components.

(2) Consumer Electronics & Home Appliances

Metal parts for housings, frames, and precision assemblies.

(3) Construction Hardware

Handles, fittings, structural components, and specialized metal parts.

4. Quality Control and Production Efficiency

(1) ISO & IATF Certified Quality Management

All processes comply with ISO 9001:2015 and IATF 16949:2016, ensuring stable mass production and high yield rates.

(2) Rigorous QC Procedures

Incoming inspection, in-process control, and final inspection include PPAP, CPK, SPC, and tensile testing for full traceability and consistent quality.

5. Customized Solutions & Technical Support

(1) One-Stop Service from Tooling to Mass Production

Integration of design, processing, assembly, testing, and production shortens time-to-market.

(2) Engineering Guidance

Forming analysis, structural optimization, and production feasibility evaluation to tailor solutions for each client.

(3) Rapid Prototyping & Small-Batch Support

Early-stage samples and trial production help verify designs before full-scale manufacturing.

6. How to Choose the Right Metal Stamping Process for Your Project

(1) Understand Your Product Requirements

Before selecting a stamping process, define your product’s size, material, strength, and tolerance needs.

Hydraulic press forming is ideal for thick, high-strength parts requiring deep drawing, while progressive die stamping is suited for smaller, high-volume precision components.

(2) Evaluate Production Volume and Cost

For large-scale, continuous production, progressive dies reduce material waste and cycle time.

For low- to medium-volume runs, hydraulic press forming offers flexibility and lower tooling cost.

(3) Consider Material and Forming Complexity

If your design involves deep shapes or thick plates, choose hydraulic forming for stability and surface quality.

For multi-stage forming with intricate geometry, progressive dies deliver consistent accuracy.

(4) Consult with Experts for Process Optimization

Maw Hung’s engineering team provides forming analysis, material selection guidance, and die design optimization to ensure cost-effective, high-quality production tailored to your industry.

7. Medium & Large Hydraulic Press and Progressive Stamping FAQ

FAQ 1: What is the difference between hydraulic press forming and progressive stamping?

Hydraulic press forming is suitable for large, thick, and high-strength components that require deep drawing and precise forming.

Progressive die stamping, on the other hand, is ideal for small to medium-sized components that require high-speed production and consistent precision.

FAQ 2: How can I choose the right metal stamping process for my project?

The best process depends on your material type, part size, production volume, and budget.

Hydraulic presses are perfect for complex, heavy-duty parts, while progressive dies excel in high-volume, high-accuracy applications.

You can also consult Maw Hung’s engineering team for professional evaluation and process optimization.

FAQ 3: What is the tonnage and size range of Maw Hung’s stamping machines?

Maw Hung’s hydraulic presses range from 200 to 800 tons, capable of processing steel and aluminum sheets from 0.5mm to 8mm thick, depending on material properties and forming requirements. The maximum die design size can reach up to 2500 × 1000 mm, which may vary based on tooling configuration, product geometry, and production needs.

FAQ 4: Does Maw Hung provide tooling design and manufacturing services?

Yes. Maw Hung has an in-house tool design and manufacturing department that develops progressive, compound, and single-stage dies to ensure long life and high precision.

FAQ 5: How Does Maw Hung Handle Material Processing?

Maw Hung specialize in different material types. High-Tensile Steel, Stainless Steel, Aluminum Alloys, Other Specialty Metals

7. Contact Maw Hung for Metal Stamping Solutions

Contact Information

Maw Hung Industrial Co., Ltd.

No. 371, Section 3, Zhangcao Road, Hemei Township, Changhua County, Taiwan

TEL: +886-4-7612296 | Email: mawhung7612296@gmail.com