Maw Hung|Comprehensive QA & QC Metal Stamping System

Maw Hung implements QA, QC, DQC, IQC, IPQC, FQC, and OQC to ensure products meet standards, enhance quality, and improve vehicle supply chain reliability.

Table of Contents

1、Quality Assurance & Control Overview

2、Testing and Inspection Procedures

3、Continuous Improvement for Vehicle Supply Chain Reliability

4、Customer-Centric Quality Management

5、FAQ

1、Quality Assurance & Control Overview

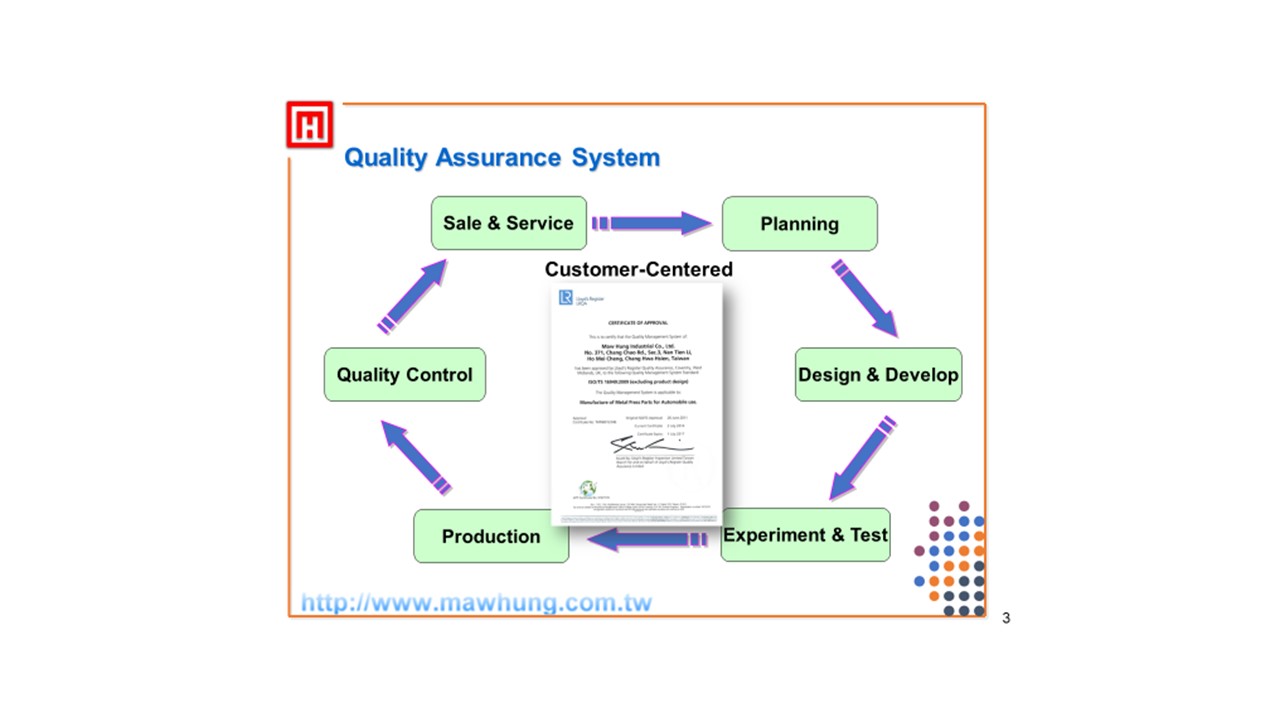

Maw Hung maintains a robust Quality Assurance (QA) and Quality Control (QC) system, integrating DQC, IQC, IPQC, FQC, and OQC processes.This comprehensive system ensures every product meets international quality standards, reducing defects and enhancing reliability for clients in the vehicle supply chain and other industries.

2、Testing and Inspection Procedures

All products undergo strict testing and inspection at each production stage.IQC (Incoming Quality Control): Inspect raw materials to ensure compliance with specifications.IPQC (In-Process Quality Control): Monitor production processes to prevent defects early.FQC (Final Quality Control): Conduct final inspections to verify finished product quality.OQC (Outgoing Quality Control): Confirm products meet client requirements before shipment.These processes guarantee that outputs consistently meet standards and customer expectations, minimizing waste and enhancing overall product reliability.

3、Continuous Improvement for Vehicle Supply Chain Reliability

Maw Hung implements continuous improvement programs to enhance quality, reduce variation, and prevent defects.Our QA & QC framework ensures that metal stamping products and components not only meet technical specifications but also support the reliability and efficiency of the vehicle supply chain, providing high-quality solutions to global clients.

4、Customer-Centric Quality Management

By focusing on customer needs and product performance, Maw Hung ensures that products or services consistently meet standards.Our dedicated QA/QC teams analyze feedback, refine processes, and implement improvements to further enhance product quality and customer satisfaction.